CPC's current industrial safety and healthcare policy: focal points

●

CPC has implemented the Taiwan Occupational Safety and Health Management System

(TOSHMS) and works at continuous improvement of its operations environment.

●

Reinforcement of contractors' safety management practices and establishment of contractor

self-discipline in order to reduce occupational accidents among contractors' employees.

●

Regular review of industrial safety and health regulations and continuous review and revision

of standard operating procedures.

●

Strengthening of industrial health management, scheduling employee health checks, analysis

and tracking of health check-up information, promotion of a healthy lifestyle and emphasis

on the mental health of employees.

●

Implementation of risk management and process safety management, establishment of

equipment safety management processes, thorough implementation of oil tank and pipeline

inspections and installation of long-distance oil and gas pipeline monitoring and leak

detection systems.

●

Strengthening of fire-prevention drills, organization of a professional fire-fighting team and

guidance to work units on carrying out fire-appliance performance testing. Five technical

manuals on fire-control equipment have been published.

●

Implementation of graded on-site safety inspections; continuous improvement through

safety observations at the systemic, management and implementation levels.

●

Strengthening of industrial safety inspections including "management by walking around"

by senior managers, professional industrial safety inspections and pre-startup inspections

of new and renovated factories. All deficiencies that are discovered are tracked through the

information system and dealt with.

●

Planning and implementation of safety and environmental training and awareness programs,

development and provision of online study courses, establishment of an industrial safety test-

question database and compilation and publication of instructional accident case studies.

●

Reinforcement of the functions of the Safety Information Center, lending of study materials

and availability of an online data query service system.

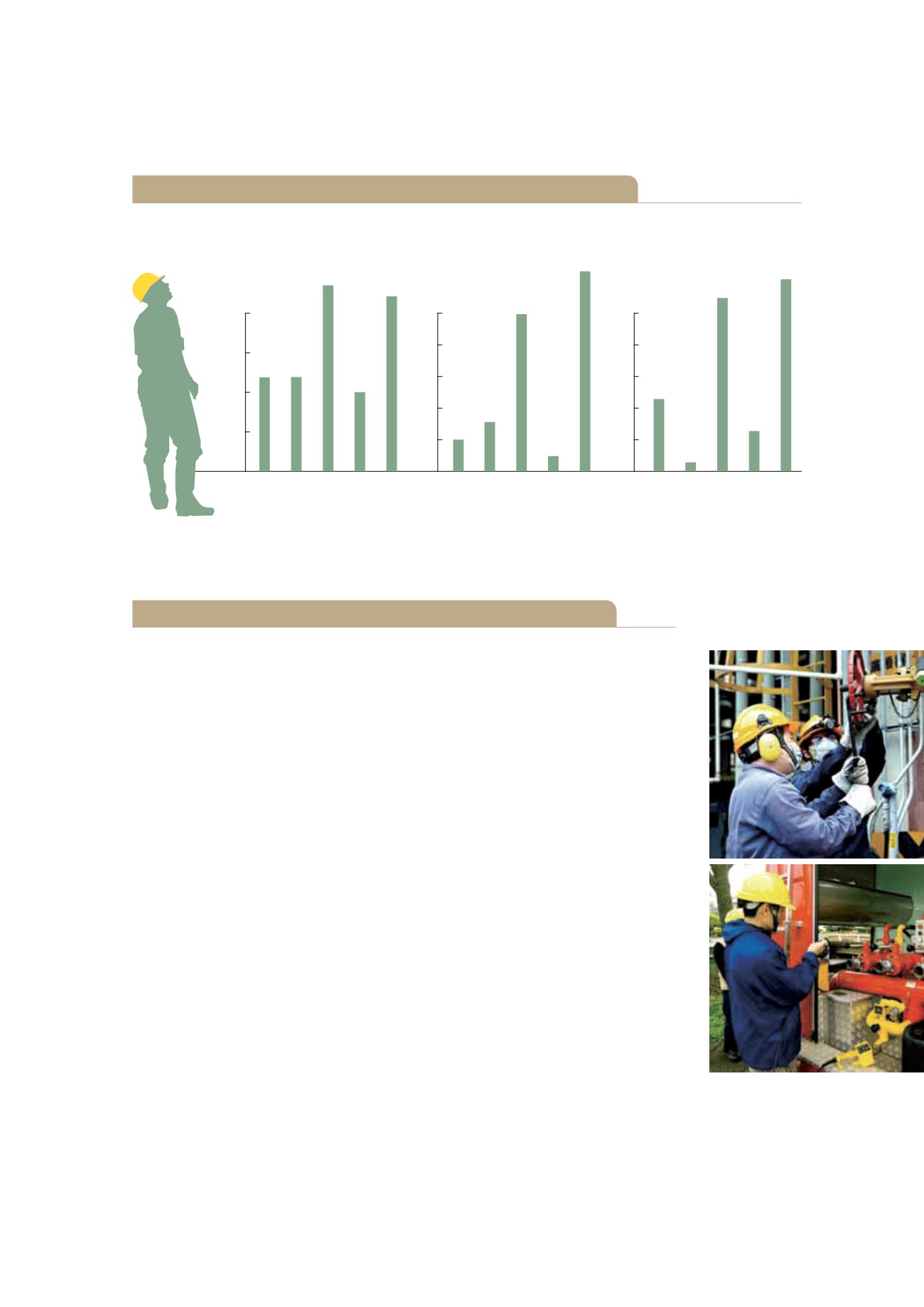

Frequency of

disabling injuries

Severity rate of

disabling injuries

Frequency-severity indicator

for occupational injuries

CPC's occupational accident statistics for the most recent five years

2009 2010

2012 2013

2011

0.18 0.18

0.15

0.34

0.37

0.075

0.150

0.225

0.300

2009 2010

2012 2013

2011

4

6

2

381

20

4

8

12

20

16

2009 2010

2012 2013

2011

0.87

1.05

0.54

11.38

2.72

0.4

0.8

1.2

1.6

2.0

Explanation: The two accidental deaths that occurred in 2013 - one in the Exploration Business

Division in the course of horizontal drilling; one due to hydrogen sulfide poisoning at the

Kaohsiung Refinery - are the chief reasons for rise in that year's accident indicator.

│

23

│

Industrial Safety and Health