CPC is engaged in a long-term initiative to improve the way in which it handles issues arising from pollution involving waste-water,

air, noise, solid waste and groundwater in the context of fulfilling its CSR commitment and upholding the spirit of sustainable

development. In recent years, the company has also worked on carbon dioxide emission inventory and reduction projects,

and has adopted the best internationally-available control technology and equipment for all of its new investment projects in

order to minimize the pollution caused by production, transportation and storage processes. CPC has also sought to improve

environmental protection by upgrading the quality of its petroleum products.

CPC consistently adheres to an environmental protection policy characterized by legal and regulatory compliance, adherence

to international norms, pollution prevention, energy conservation, waste reduction, continuous improvement, employee

participation, social responsibility, and sustainable development. Since 1989 it has invested more than NT$50 billion in

environmental protection; the ISO 14001 environmental management system has been implemented in all units since 1995 and

22 units had passed certification by the end of 2014. In keeping with global trends, a company-wide environmental accounting

system was set up in 2004 to help improve performance in environmental matters.

Although Taiwan is not a signatory to the 1997 Kyoto Protocol, CPC works in alignment with international environmental

protection practice in reducing the company's greenhouse gas emissions. We have established carbon dioxide reduction targets

and timetables for existing plants, and practice emissions-reduction measures by using low-carbon fuel, conserving energy,

improving equipment efficiency and reducing waste.

A company-wide inventory of greenhouse gases was completed in 2005, and there is an ongoing CO

2

reduction plan. The plan's

CO

2

emission reduction target of 1 million tons by 2009 was surpassed by achieving an actual reduction of 1.22 million tons.

The goal of the second stage of the reduction plan is to cut CO

2

emissions by a cumulative total of 2.3 million tons by 2015; a

reduction of 2.53 million tons had been achieved as of the end of 2014 and work on further reducing emissions continues.

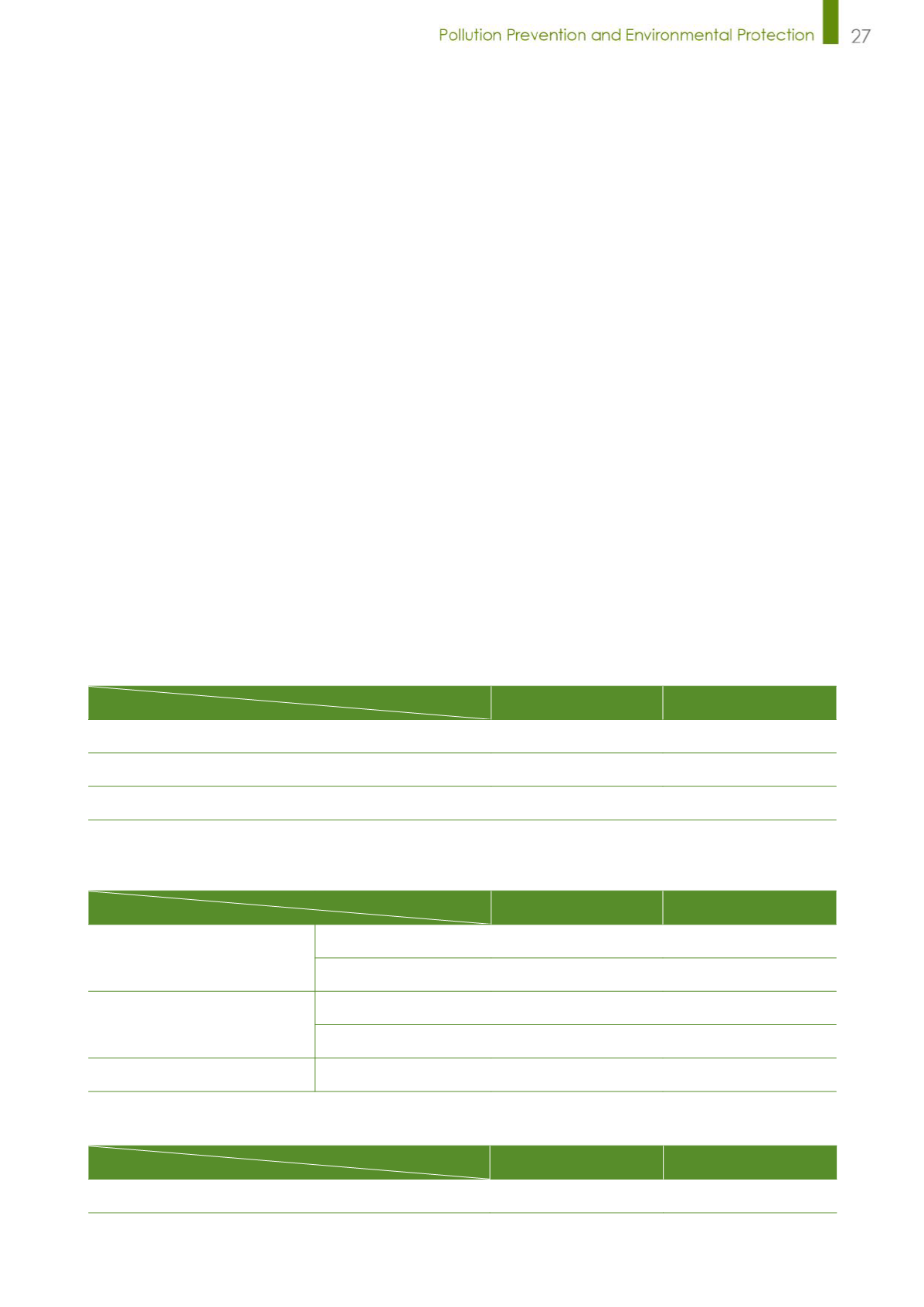

Comparison of CPC Refineries' Environmental Quality and National

Standards

Effluent

Item

Year

2014 quality

Current national standards

Chemical oxygen demand (COD) (ppm)

< 60

100

Oil (ppm)

< 5

10

Suspended solids (ppm)

< 15

30

*Monthly average value

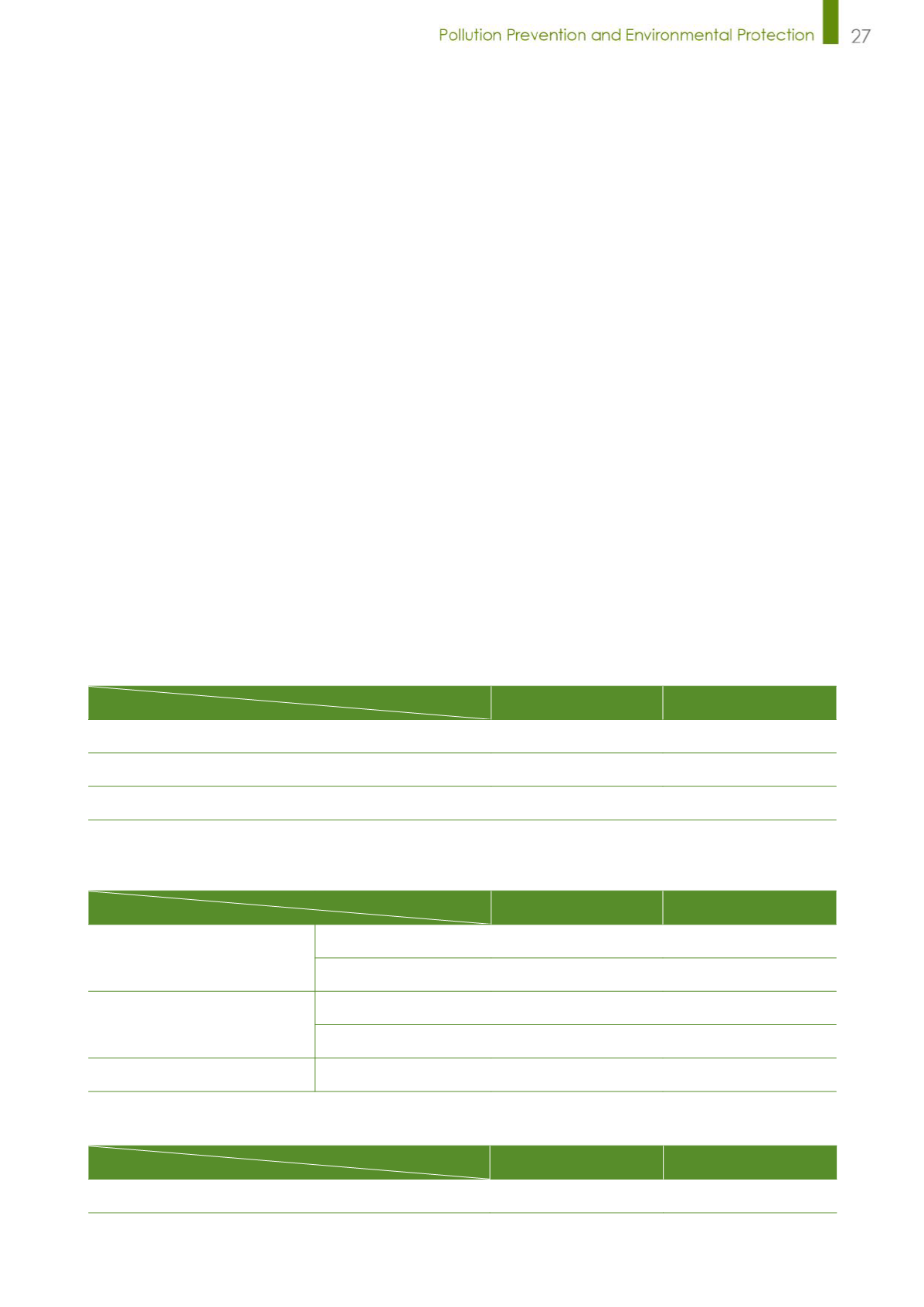

Stack gas

Item

Year

2014 quality

Current national standards

Sulfur oxides (SOx) (ppm)

Gaseous fuel

< 50

100

Liquid fuel

< 250

300

Nitrogen oxides NOx (ppm)

Gaseous fuel

< 100

150

Liquid fuel

< 200

250

Particulate matter (TSP) (mg/Nm

3

)

Set based on displacement

5-100

< 25-500

Noise

Item

Year

2014 quality

Current national standards

Nighttime (dB)

< 50

55