Establishing safety regulations and accident-prevention standards

Industrial safety is the foundation of corporate development. To achieve its goal of "100% industrial safety and 0% accidents",

CPC is constantly strengthening its safety culture through actively pursuing a policy based on safety disciplines, thorough

inspection, promotion of well-being and responsible healthcare, risk management and systematized operations – and in which

employee participation and continuous improvement are key elements. CPC's industrial safety performance has been recognized

not only at home but also internationally, as shown by the medal awarded by the World Safety Organization in 2005.

CPC's industrial safety and health policy – the focal points

In line with its emphasis on a culture of industrial health and safety, CPC is putting particular effort into the following focal

points, and is working particularly hard at raising awareness and team spirit among both employees and external vendors in the

interest of creating a safe and comfortable working environment.

•

Implementation of the Taiwan Occupational Safety and Health Management System (TOSHMS) and continuous improvement

of its operating environment.

•

Reinforcement of contractors' safety management practices and establishment of contractor self-management in order to

reduce occupational accidents among their employees.

•

In conjunction with the implementation of occupational safety laws, periodic review of industrial safety and health regulations

and continuous review and revision of standard operating procedures.

•

Strengthening of industrial health management, scheduling employee

health checks, analysis and tracking of health check-up information,

promotion of healthy lifestyles and emphasis on the importance of

employees' mental health.

•

Implementation of risk management and process safety management,

establishment of equipment safety management processes, thorough

inspections of oil tanks and pipelines and the installation of monitoring

and leak detection systems on long-distance oil and gas pipelines.

•

Strengthening of fire prevention and response capabilities; organization

of a local joint emergency response organization ensuring that

manpower, facilities, equipment and emergency response and rescue

gear in all units are mutually supporting so that the impact of fires

and other disasters can be minimized.

•

Implementation of graded on-site safety inspections, continuous

improvement through safety observations at the systemic, equipment

and implementation levels and increased awareness of the importance

of industrial safety disciplines.

•

Strengthening of industrial safety inspections including "management

by walking around" by senior managers, professional industrial safety

inspections and pre-operational inspections of new and renovated

work sites. All deficiencies that are discovered are tracked through

the information system until improvements have been completed.

•

Planning and implementation of safety and environmental training

and awareness programs, development and provision of online study

courses, establishment of an industrial safety test-question database and

compilation and publication of accident case-study teaching materials.

•

Reinforcement of the functions of the Safety Information Center, lending

of study materials and availability of an online data query service system.

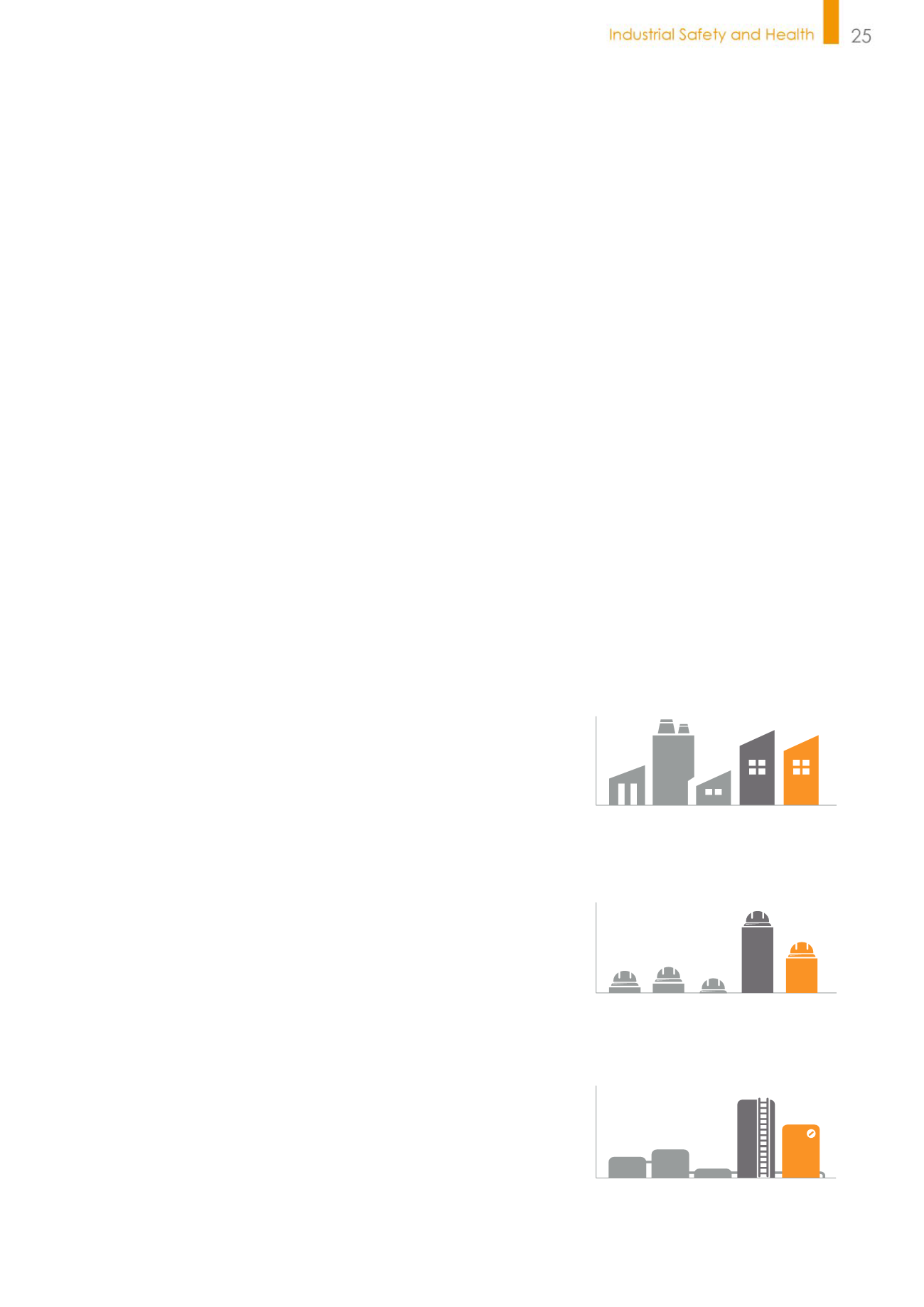

CPC's occupational accident

statistics for the past five years

Frequency of disabling injuries

0

0.1

0.2

0.3

0.4

0.18

0.15

0.31

0.34

0.37

2010 2011 2012 2013 2014

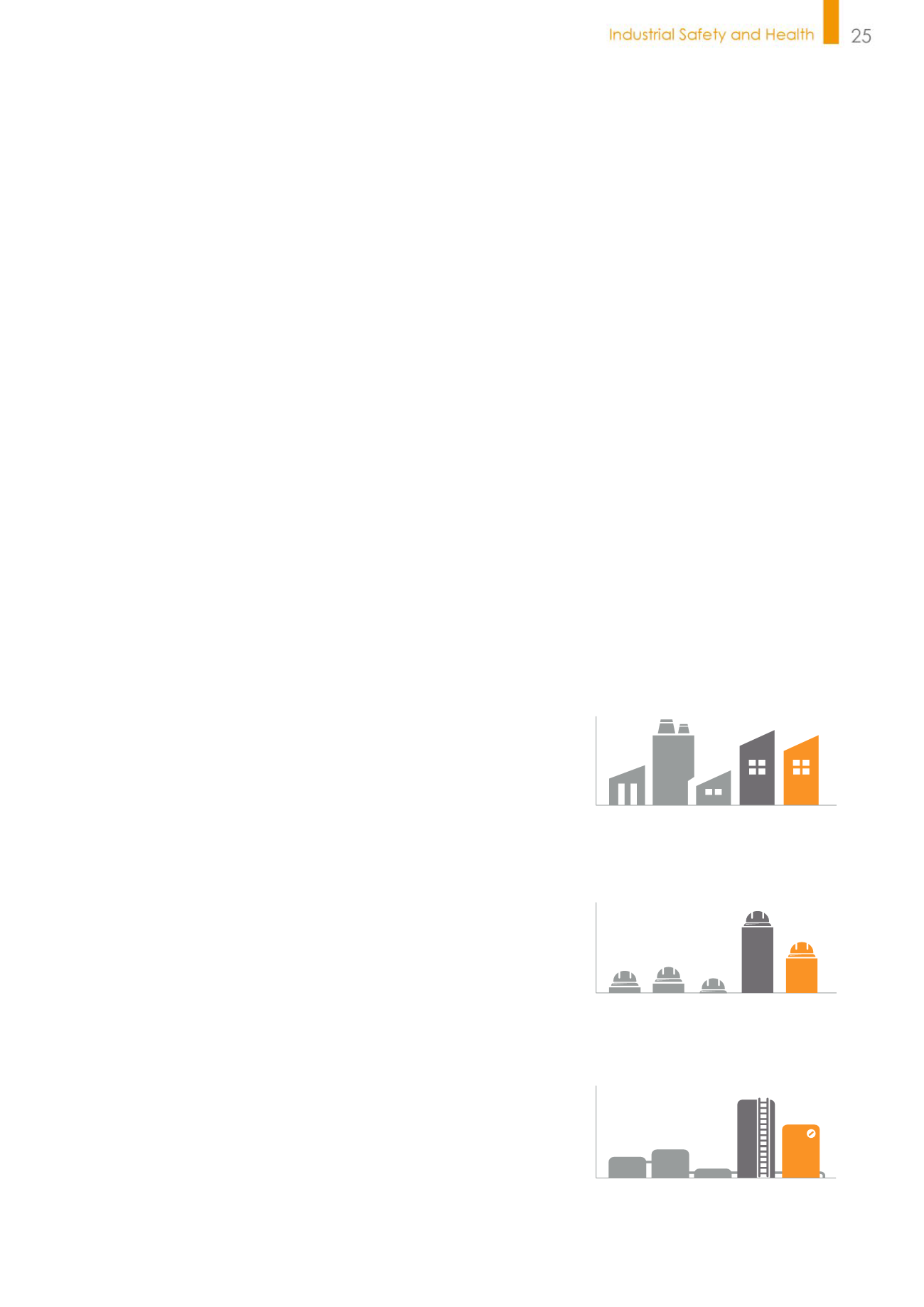

Severity rate of disabling injuries

6

0

100

200

300

400

20

2

381

190

2010 2011 2012 2013 2014

Frequency-severity indicator for occupational injuries

1.05

2.72

11.38

7.67

0.54

0

3

6

9

12

2010 2011 2012 2013 2014